Top Guidelines Of Motorcycle Parts New Zealand Specialists

Table of ContentsHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.Some Known Factual Statements About Motorcycle Parts New Zealand Specialists Some Known Questions About Motorcycle Parts New Zealand Specialists.7 Easy Facts About Motorcycle Parts New Zealand Specialists DescribedExcitement About Motorcycle Parts New Zealand SpecialistsThe Facts About Motorcycle Parts New Zealand Specialists RevealedMotorcycle Parts New Zealand Specialists Fundamentals ExplainedThe Motorcycle Parts New Zealand Specialists Statements

So, get to out to one of our professionals today.CNC machining innovation is rapidly coming to be the prime focus of several production procedures around the world as a direct result of its several benefits over other techniques. Furthermore, the sectors that produce motorbikes have actually jumped on board with this trend. The most cutting-edge business are currently creating their engine elements and wheels making use of machining strategies initially established for motorcycle components.

On the other hand, the impacts of market are the main focus of this article. Allow's obtain directly right into it. You may be questioning why we utilize. It is not hard to fathom the factors that resulted in this result. Now that we have your focus let us discuss the reasoning behind this modern-day growth in the bike production industry.

The Greatest Guide To Motorcycle Parts New Zealand Specialists

Additionally, you have complete control over the appearance of the components, even to the min information. Periodically, motorcyclists might make a decision to fix up their experience by installing aftermarket parts or modifying the bike's transformation. Once more, computer mathematical control (CNC) machining is one of the most practical technique. Upgrades may be of any kind and style you want.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Discussing

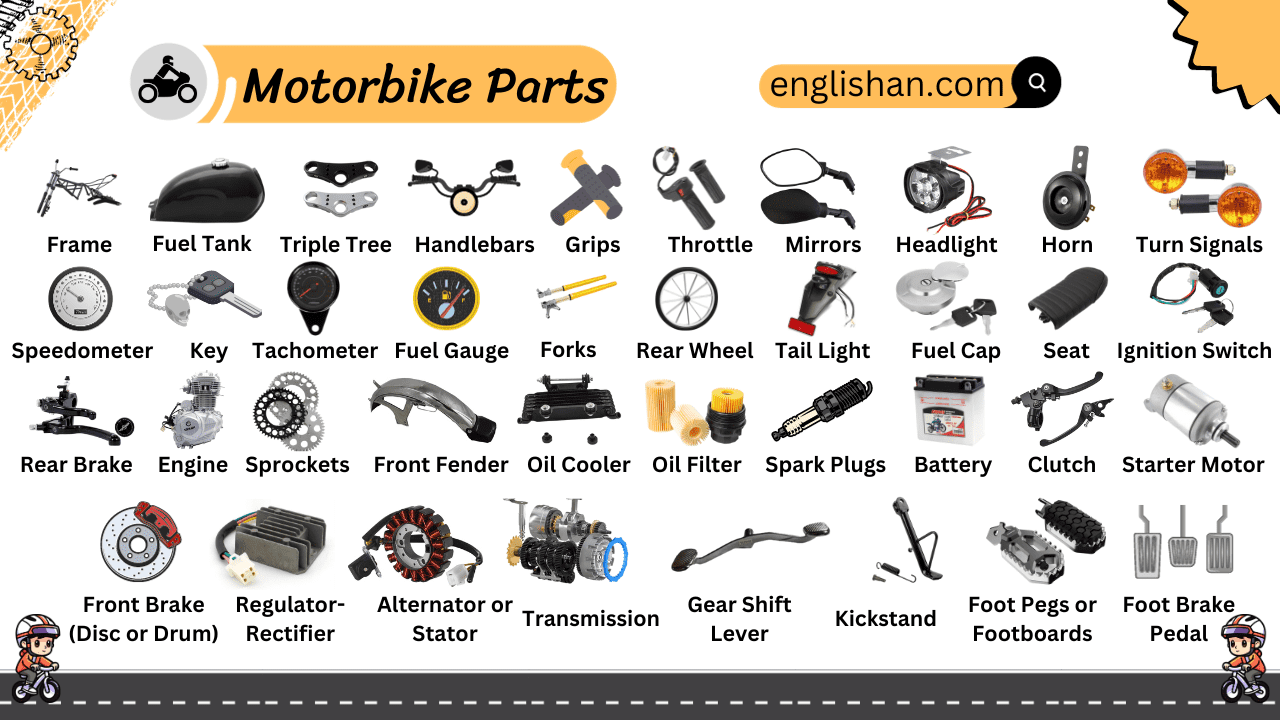

CNC machining may be used to make practically all of a motorcycle's steel and plastic elements. To proceed, we'll talk about several machined components for motorcycles. As opposed to those on autos, wheels on bikes often tend to be extra evident. Consequently, the bike's looks might be boosted with the appropriate customization of these wheels.

Milling treatments are utilized to obtain the desired degree of wheel customization. An additional facet of the motorbike that might be individualized is the tires.

5 Simple Techniques For Motorcycle Parts New Zealand Specialists

When it concerns a vehicle (or a motorbike), the most crucial component is the engine. Numerous individuals mention it as the "heart" of the car. On the other hand, the camshaft, the cyndrical tube head, and the pistons tend to be elaborate and require styles with a high degree of accuracy.

Lights is an additional facility aspect of modification. Use only high-grade products, however, considering that these lights are essential for the safety and security of motorcyclists and other motorists or individuals on the road, particularly in the evening. Motorbike fronts lights have three primary components: the light bulb, or light, the lens, and the housing. Particularly, we customize the lens and the real estate.

Milling processes with a remarkable coating would result in the lenses having a reflective top quality that resembles that of a mirror. The cover, on the other hand, is not made up of vulnerable products; rather, it is built out of difficult polymers that can be machined into more intricate patterns.

An Unbiased View of Motorcycle Parts New Zealand Specialists

Motorcycle makers commonly cast these elements, yet just for the production of bespoke parts. Machining on 5 axes in today's globe is the methods by which any style shape may be recognized.

Pick Runsom for your personalized bike components! We have the capacity to produce challenging and stylish elements making your motorcycle matchless.

Below are a few instances of steels usually used in bike part machining. Aluminum is the main product made use of by firms focusing on producing custom-made motorcycle parts to create the majority of these components. In the past, we would develop our engines out of actors iron. On the other hand, aluminum is promptly coming to be the product of selection, partly because of the truth that it is a lot visit the site more light-weight.

Zinc describes an additional metal that is very light in weight and has great machining high qualities because of its high mechanical strength. This material might be developed into nearly any kind of shape and keeps its measurements well. Even mission-critical components that need a high degree of accuracy might profit from their use.

Getting The Motorcycle Parts New Zealand Specialists To Work

An additional steel that sees heavy use in the manufacturing of CNC-customized elements is magnesium. It is among the lightest metals that are now obtainable and has exceptional machinability features and stamina proportionate with its reduced weight. One of the downsides of magnesium is that its dust might conveniently ignite.

Because of its exceptional machinability and weldability, stainless steel is an alloy that is especially appropriate for CNC processes. They have great deterioration resistance and a high visual allure. Their most usual use in generating numerous motorcycle elements is bolts, such as screws and screws. Their low vulnerability to oxidation and deterioration makes them suitable for this use.

How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

It appears that CNC transforming and grating are the fundamental procedures. Different techniques exist, such as drilling. Let's check out most of these machining methods detailed. The CNC turning method is thought about a subtractive production method. In enhancement, it needs keeping bars of material, most usually plastic or steel, ready and after that turning a cutting tool to eliminate sections of the material as the product is turned.

These approaches are equally essential and generate components with high precision and constant top quality. The processes aid improve the total top quality of the machined bike components.

Some Of Motorcycle Parts New Zealand Specialists